Our manufacturing facilities

The manufacturing process at LLC SalesSolution is based on modern technologies, strict quality control, and many years of industry experience.

We provide a full production cycle for pipeline components — from raw material preparation to final product testing. This enables us to guarantee the reliability, durability, and compliance of our products with the highest industry standards.

LLC SalesSolution holds valid Declarations of Conformity with the technical regulations of the Eurasian Economic Union (Customs Union Technical Regulations):

TR CU 010/2011 “On the safety of machinery and equipment” (Registration No.: EAEU N RU D-RU.RA08.B.75385/24)

TR CU 010/2011 “On the safety of machinery and equipment” (Registration No.: EAEU N RU D-RU.RA08.B.75385/24)

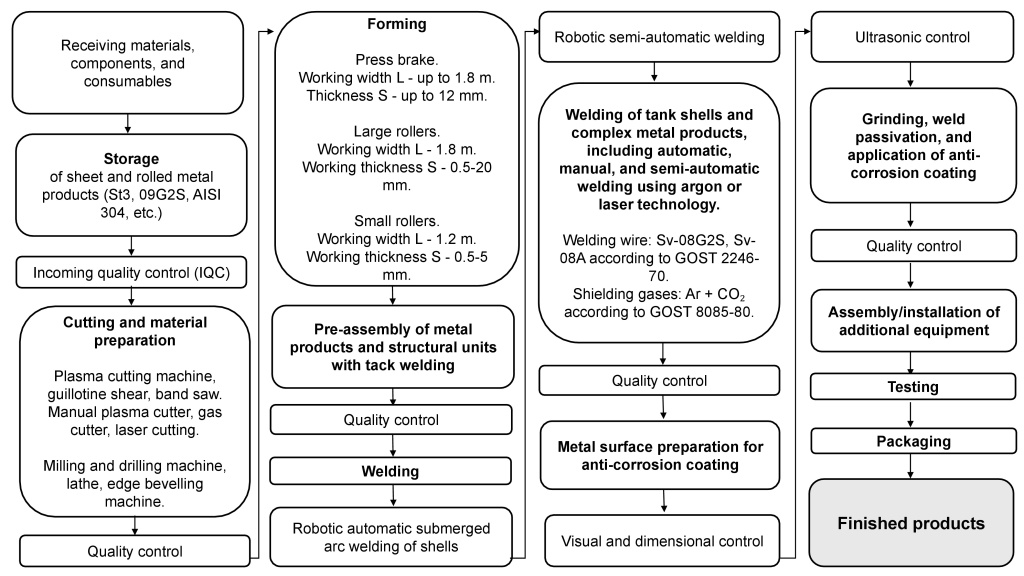

Production Stages:

- Material Receipt and Storage

Incoming materials, components, and consumables (including sheet and section metal) are delivered to the facility. All materials undergo initial incoming quality control (QCD) before being stored. - Material Cutting

Sheet metal is cut using precision equipment: plasma cutters, guillotines, band saws, laser and gas cutters. The resulting parts are checked by QCD for size and shape accuracy.

- Machining

Parts are processed on milling, drilling, and turning machines, as well as edge-beveling equipment, to achieve the required geometry and compliance with project documentation. All operations are followed by quality checks.

- Forming

Metal sheets and sections are shaped using press brakes. Cylindrical or curved parts are formed using rolling machines, allowing for processing of various metal types and thicknesses. Edges are treated and checked before assembly.

- Pre-Assembly

Prepared parts are tack-welded into subassemblies and structures. Temporary fixtures are applied for positioning before final welding. Intermediate quality control is conducted at this stage.

- Welding

We use robotic submerged arc welding, semi-automatic shell welding, and manual, automated, and argon/laser/CO₂ welding depending on the component. Welding wire complies with GOST standards. Weld seams undergo thorough inspection. - Surface Treatment

Structures are prepared for anti-corrosion coating (ACC) through grinding, weld passivation, and other treatments. Protective coatings are then applied to ensure long-term durability.

- Final Assembly and Outfitting

Additional components and equipment are installed. Products undergo test trials to confirm compliance with all technical requirements.

- Packaging and Shipment

Finished products are carefully packaged and shipped to the customer, completing the production cycle.

Production is carried out at the “KS Mechanica” plant, located at: 23A Bugulminskaya Street, Leninogorsk, Republic of Tatarstan, Russia, 423255

LLC SalesSolution also has representative offices in the UAE and China.

Send requests

Fill out the form to submit a request for the purchase of our products or to receive the necessary advice. Our manager will contact you as soon as possible.

0%