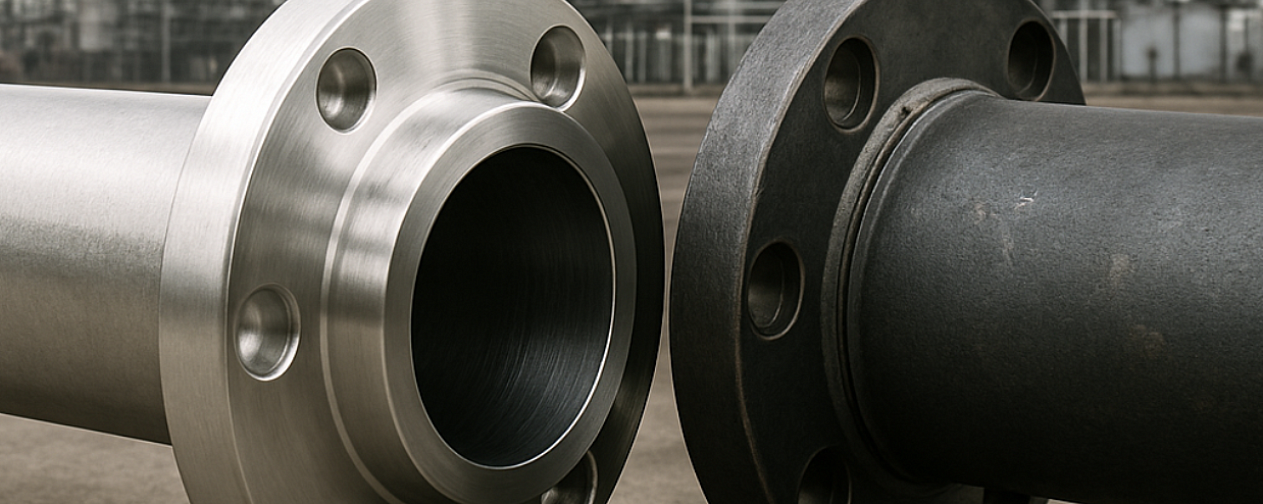

When designing pipelines for the oil & gas, chemical, and power industries, special attention is paid to the choice of material. Reliability, safety, and service life of the equipment directly depend on it. The most commonly used materials are stainless steel, carbon steel, titanium, and nickel alloys. In this article, we will look at why nickel alloys are becoming an increasingly popular solution and what advantages they offer.

Advantages of Nickel Alloys in Pipeline Systems

Nickel alloys provide exceptional resistance to aggressive chemical environments, high temperatures, and mechanical loads. They are ideal for applications where other materials lose strength or corrode quickly. Among the most well-known nickel alloys are Inconel®, Hastelloy®, Monel®, and Alloy 625/825.

Key benefits of nickel alloys:

Comparison with Other Materials

Stainless Steel

Widely used in industry, especially grades 304/316. However, under prolonged exposure to aggressive reagents and high temperatures, it loses resistance and requires regular monitoring. Unlike nickel alloys, its service life in chemical plants is 10–20 years, with risks of intergranular corrosion.

Carbon Steel

The most affordable and common material. Rarely used without protective coatings or anti-corrosion treatments in chemical and petrochemical industries. Service life is less than 10 years, with high susceptibility to corrosion even at moderate temperatures.

Titanium

Known for high strength and resistance to most acids, especially in seawater. However, it is difficult to process and weld, and it is expensive. In extreme temperature conditions or in the presence of fluorine-containing media, it is less resistant than nickel alloys.

Where Are Nickel Alloys Used?

Nickel alloys are widely applied in the following sectors:

Choosing nickel alloys is a strategically justified decision when working in aggressive and high-temperature environments. Despite a higher initial cost, they provide durability, minimize downtime, and comply with international ASME standards.

If your company operates in the oil & gas, chemical, or power industries and you are looking for a reliable solution for pipeline systems and pressure equipment, nickel alloys are an investment in stability and safety for years to come.

Source: Centerway Steel – “Nickel Alloy Pipe vs Other Materials: Comparison”

https://www.centerwaysteel.com/newsdetail/nickel-alloy-pipe-vs-other-materials-comparison.html

Advantages of Nickel Alloys in Pipeline Systems

Nickel alloys provide exceptional resistance to aggressive chemical environments, high temperatures, and mechanical loads. They are ideal for applications where other materials lose strength or corrode quickly. Among the most well-known nickel alloys are Inconel®, Hastelloy®, Monel®, and Alloy 625/825.

Key benefits of nickel alloys:

- High corrosion resistance in acidic, alkaline, and marine environments

- Excellent heat resistance (up to 1000 °C and above)

- Long service life (30 years or more in aggressive conditions)

- Good weldability and resistance to deformation

- Reduced operational risks and lower maintenance costs

Comparison with Other Materials

Stainless Steel

Widely used in industry, especially grades 304/316. However, under prolonged exposure to aggressive reagents and high temperatures, it loses resistance and requires regular monitoring. Unlike nickel alloys, its service life in chemical plants is 10–20 years, with risks of intergranular corrosion.

Carbon Steel

The most affordable and common material. Rarely used without protective coatings or anti-corrosion treatments in chemical and petrochemical industries. Service life is less than 10 years, with high susceptibility to corrosion even at moderate temperatures.

Titanium

Known for high strength and resistance to most acids, especially in seawater. However, it is difficult to process and weld, and it is expensive. In extreme temperature conditions or in the presence of fluorine-containing media, it is less resistant than nickel alloys.

Where Are Nickel Alloys Used?

Nickel alloys are widely applied in the following sectors:

- Oil & Gas — pipelines for transporting corrosive fluids, refinery piping, internal elements of heat exchangers.

- Chemical Industry — reactors, columns, storage equipment in contact with aggressive media.

- Engineering and Power Generation — steam turbine components, heaters, heat exchangers, pressure vessels.

- ASME-compliant Equipment — tanks, boilers, autoclaves made of Alloy 625 and 825.

Choosing nickel alloys is a strategically justified decision when working in aggressive and high-temperature environments. Despite a higher initial cost, they provide durability, minimize downtime, and comply with international ASME standards.

If your company operates in the oil & gas, chemical, or power industries and you are looking for a reliable solution for pipeline systems and pressure equipment, nickel alloys are an investment in stability and safety for years to come.

Source: Centerway Steel – “Nickel Alloy Pipe vs Other Materials: Comparison”

https://www.centerwaysteel.com/newsdetail/nickel-alloy-pipe-vs-other-materials-comparison.html